Lithography for long print runs

Lithography for long print runs

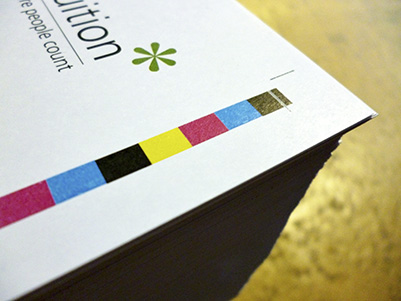

Offset printing, also called offset lithography, is a method of mass-production printing in which the images on metal plates are transferred (offset) to rubber blankets and then to the print media. The print media, usually paper, does not come into direct contact with the metal plates. This prolongs the life of the plates. In addition, the flexible rubber conforms readily to the print media surface.

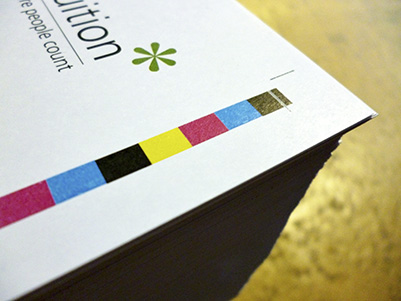

The main advantage of offset printing is its high and consistent image quality. The process can be used for medium or high-volume jobs. There are two types of offset printing machines in common use for publication today. In sheet-fed offset printing, individual pages of paper are fed into the machine. The pages can be pre-cut to the final publication size or trimmed after printing.

In web offset printing, larger, higher-speed machines are used. These are fed with large rolls of paper and the individual pages are separated and trimmed afterwards. Sheet-fed offset printing is popular for small and medium-sized fixed jobs such as limited-edition books. Web offset printing is more cost-effective for high-volume publications.